Table of Contents

You think requesting a packaging sample is simple—just send a request and wait, right?

That’s what one of my clients thought too. Until she realized her team had already delayed product development by 2 weeks because the supplier didn’t explain what was really involved.

Behind every “Sure, we’ll send a sample” is a long chain of internal work, coordination, and sometimes, bottlenecks. If you don’t know what’s happening behind the scenes, you’ll likely misjudge timelines, get frustrated, or worse—lose your launch window.

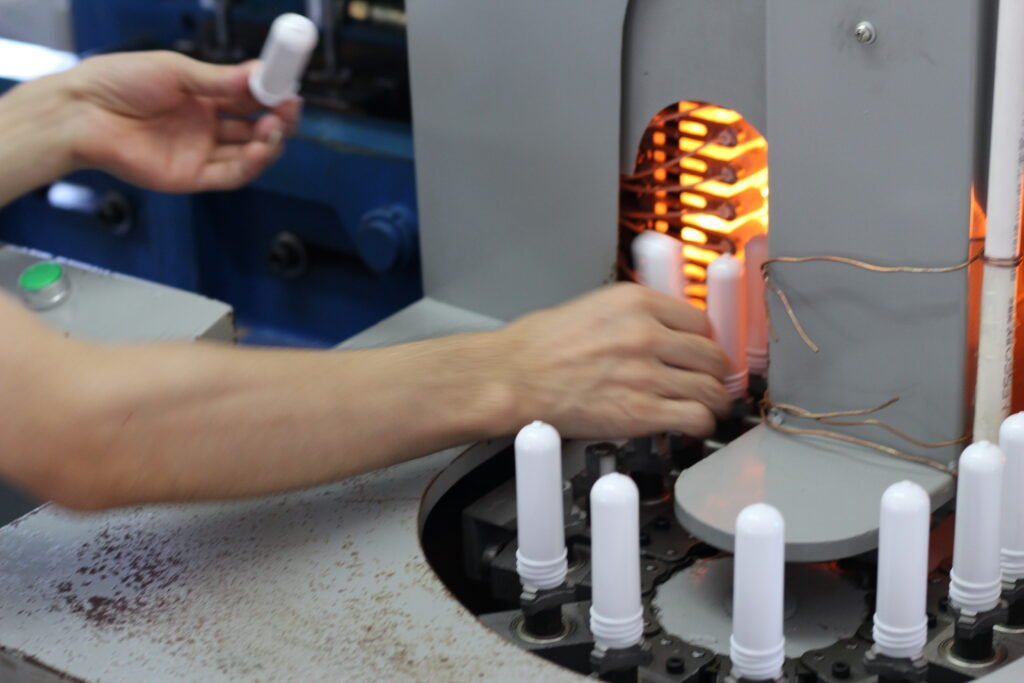

Behind every sample is a full mini production

So what actually happens after you send a sampling request?

From our experience handling hundreds of sample orders a year, here’s the real sequence of events:

First, our team reviews the request for feasibility—do we have matching stock? Do we need to custom color?

Then we coordinate with printing (if you need logo/label printing), and prep materials.

Packaging assembly, QC checks, lead time confirmations… every step is managed on a tight schedule.

Most delays or errors happen when clients don’t realize how many departments are involved.

Let’s break down what actually happens

🧩 Let’s break down what actually happens

1️⃣ Reviewing your request (1–2 days)

🔍 Your design is first reviewed by a production engineer. If it’s a standard bottle, great—it goes straight to decoration planning. If not, they’ll check whether mold modifications are needed.

2️⃣ Sample planning & component sourcing (2–3 days)

📦 We decide on how to realize your design using existing components or minor adjustments. If we don’t have a matching pump, cap, or jar in stock, sourcing begins.

3️⃣ Surface treatment (3–7 days)

🎨 This includes spray coating, metallizing, soft-touch finishes, frosted effects, etc. Each process needs setup time—and tests.

4️⃣ Printing or labeling (2–4 days)

🖨️ If you’re adding a logo, we align the artwork with the print plate. For labels, we test print alignment and adhesiveness on the sample.

5️⃣ QC and final checks (1–2 days)

✅ Even for one piece, we still check color consistency, component fit, and durability.

📌 Why does this matter to you?

Because when you know what’s really going on, you can plan smarter.

If you’re launching in 2 months, you shouldn’t wait till next week to start sampling.

Also, if you expect instant turnaround, you’re likely underestimating the complexity behind quality packaging.

🧠 So, what should you do as a brand owner?

🕐 Start earlier than you think

Sampling takes 10–15 working days in most cases. Start when your design is 80% ready.

📅 Ask for a timeline breakdown

A good supplier will walk you through what happens when.

🔁 Don’t expect perfection on round one

Good samples need iterations. What matters is speed + willingness to revise.

Real Example – Emily’s Mistake

Emily, a skincare brand manager in California, once requested 3 samples with matte pink pumps and silver collars. Sounds easy? She forgot to tell us the collar finish, and changed her logo after we had already printed it. The project was delayed by 8 days—and her new product launch had to wait.

Lesson? A sample is not “just a sample.” It’s a mini version of your supply chain in motion.

💬 Want to make the sampling process easier?

At Xumin Packaging, we’ve helped 200+ beauty brands go from idea to sample in under 2 weeks—without surprises.

We keep over 500 bottle styles in stock, support 1000pcs minimum for logo/label printing, and guide you through every decision with clear visuals and fast turnarounds.

🔍 Want to go deeper?

If this helped, you might also be wondering:

❓ How many samples should I request before placing an order?

❓ What’s the difference between decoration methods like UV vs. matte spray?

❓ How much does custom printing really cost at different quantities?

👇 We’ll break those down in upcoming posts. Stay tuned—or reach out directly for 1-on-1 support.