Table of Contents

Don’t rush into the first supplier who sends you a shiny catalog.

When I talk to brand owners, I often hear the same story: “We found a supplier on Alibaba, the samples looked fine, but when it came to the real order, nothing matched.”

Evaluating a supplier is not about who replies fastest—it’s about who can actually deliver when it matters.

1. Ask About Their Real Capabilities

The biggest risk is working with a “catalog factory” — everything looks good on paper, but in reality, they can only deliver a fraction of what they show. To judge whether a supplier is truly reliable, don’t just listen to what they say. Check what they can actually prove. Here’s what to ask:

① Production Resources & Equipment

-

Do they own the factory or outsource production?

-

How many injection machines, blow molding machines, or printing/coating lines do they operate?

👉 The more advanced the equipment, the better the stability and lead time you can expect.

② Mold & Development Capability

-

Do they own the molds or work with third-party mold makers?

-

Can they open or adjust molds based on your requirements?

👉 Suppliers with mold capability can quickly solve design or structural changes without long delays.

③ In-House Processes & Integration

-

Can they handle printing, hot stamping, coating, or metallizing in-house?

-

Do they also provide assembly, labeling, and packaging services?

👉 A supplier with complete in-house processes reduces outsourcing risks and shortens delivery time.

④ Capacity & Quality Performance

-

What’s their daily output and maximum production capacity?

-

What is their defect or rejection rate?

-

Do they hold certifications such as ISO9001 or ISO14001?

👉 Numbers speak louder than promises. A reliable supplier will be willing to share real data.

⑤ Transparency & Proof

-

Are they willing to provide production videos or QC records?

-

Can they offer third-party test reports (material safety, functional testing)?

👉 Suppliers who are confident in their capabilities are never afraid to show evidence.

📌 Takeaway:

A catalog only shows you what they want you to see. The real capability comes from asking the right questions and verifying the evidence. A trustworthy supplier won’t shy away from detailed questions — they’ll welcome the chance to prove themselves.

2. Test Their Communication, Not Just Their Price

Many buyers fall into the trap of focusing only on price. But in reality, communication matters more than cost. A poor communicator can cost you more than any discount will save.

Here’s how to test their communication:

① Speed & Quality of Response

-

Fast replies ≠ good communication.

-

A reliable supplier gives structured, detailed feedback within 24 hours — not just a one-word “yes” or “ok.”

👉 The real measure is whether their response is complete and useful.

② Ability to Understand Your Needs

-

Can they accurately repeat or summarize your requirements?

-

Do they proactively identify potential issues and suggest solutions?

👉 A good supplier “listens to understand,” not just to answer the surface question.

③ Proactiveness & Professionalism

-

Do they recommend more suitable materials or processes based on your product?

-

Beyond pricing, do they also provide lead time, packaging, or shipping details?

👉 Professional communication is often the best sign of real experience.

④ Attitude When Problems Arise

-

If samples are not ideal, do they blame others — or offer ways to improve?

-

If production is delayed, do they inform you early and propose a solution?

👉 The right partner faces problems directly, instead of hiding from them.

3. Check Flexibility with MOQ and Customization

Many factories will push you to start at 10,000 pcs, but for a growing brand, that’s often unrealistic. A supplier who truly understands brand needs will offer flexibility in MOQ and customization.

① Support for Small Batches

-

Can they print logos and labels starting from 1000 pcs?

-

Do they offer standard bottles that can be decorated quickly?

👉 Lower MOQs allow you to test the market without the burden of huge inventory.

② Stock Bottles + Quick Decoration

-

Do they keep stock of common bottle styles?

-

Can they apply coating, printing, or hot stamping within short lead times?

👉 Stock bottles with quick decoration = saving mold costs and cutting delivery time.

③ Color & Structural Customization

-

At what volume can you customize colors? (usually 5000 pcs and above)

-

If structural changes are needed, do they offer mold development options?

👉 Clear customization rules help you plan your product launches realistically.

④ Attitude Toward Small vs. Large Orders

-

Do they only welcome big orders?

-

Do they still pay attention to smaller orders?

👉 The right supplier grows with your brand — not just push for high-volume deals.

4. Ask for References or Case Studies

A supplier with real international experience won’t be afraid to show their track record. References and case studies reveal whether they can truly support your brand.

① Look for Real Projects

-

Can they share past projects with overseas brands?

-

Do the cases include order quantity, customization details, and lead time?

👉 Vague stories don’t count — real numbers and outcomes matter.

② References & Reputation

-

Can they provide references from long-term clients?

-

Do they have verifiable reviews on platforms (e.g. Alibaba, Made-in-China)?

👉 Third-party voices carry more weight than self-promotion.

③ Growth Stories from Small to Large Orders

-

Have they helped a small brand grow from a few thousand units to tens of thousands?

-

Can they show how they supported clients with quick delivery and strict QC?

👉 This proves whether they truly understand brand growth stages.

④ How They Present Cases

-

Do they have a PPT, PDF portfolio, or website section with case studies?

-

Are the cases backed up with photos, data, or even anonymized client feedback?

👉 Suppliers who document their work well usually deliver more professionally, too.

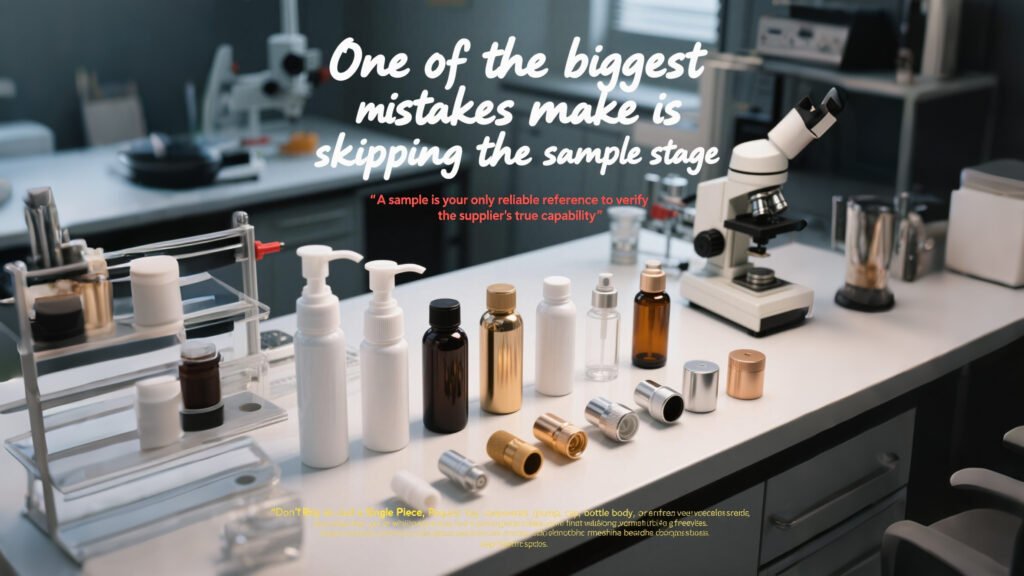

5. Never Skip the Sample Stage

One of the biggest mistakes brands make is skipping the sample stage. A sample is your only reliable reference to verify the supplier’s true capability.

① Don’t Rely on Just a Single Piece

-

Instead of asking for “extra free samples,” request key components (pump, cap, bottle body) or different finishing versions for comparison.

-

If you need several pieces to test consistency, make it clear you are willing to pay for additional samples — this shows professionalism and avoids misunderstandings.

👉 The goal is to check consistency and details, not to get freebies.

② Simulate Real Use Cases

-

Fill with your actual formula to test chemical resistance and durability.

-

Check pump rebound smoothness and whether bottles scratch during shipping.

③ Keep Reference Samples

-

Ask both sides to keep one approved sample as a reference for mass production.

④ Beware of Suppliers Who Skip Samples

-

If they push you straight into mass production without sampling, that’s a major red flag.

-

Responsible suppliers will encourage sampling, because it reduces risk for both sides.

Final Thought: Choosing a Supplier Is Choosing a Partner

At the end of the day, choosing a supplier is really about choosing your business partner. A supplier isn’t just selling you bottles — they’re holding:

-

Your launch timeline (can they deliver on time?)

-

Your brand image (is the product quality consistent?)

-

Your budget and profit margin (are costs transparent and under control?)

The best supplier is never simply the cheapest one. It’s the one who ensures you can sleep well at night without worrying about production failures.

If you treat suppliers as a short-term transaction, you may end up switching frequently and increasing risk. But if you find a true partner, they’ll help you solve problems, optimize solutions, and save your brand from costly detours.