Table of Contents

When the Order Arrives, Responsibility Begins

For most buyers, placing an order feels like the start of production.

But in a professional packaging factory, it’s actually the beginning of quality control.

Once we receive your PO, our system doesn’t just schedule production — it activates a complete QC workflow: mold verification, raw material testing, first-piece approval, and in-line inspection plans.

Every step before the first product is molded is designed to reduce risk and ensure that what you finally receive matches the confirmed sample.

In B2B manufacturing, consistent quality doesn’t depend on luck or individual effort — it comes from a verified process.

From the moment we receive your order, every stage follows a standardized control system — that’s what keeps mass production consistent with your approved sample.

Mold Verification: The First Step to Ensure Production Accuracy

Every new order — even a repeat one — starts with a mold recheck.

Many buyers assume that once a mold is opened, it can be used indefinitely.

But in manufacturing, molds are like precision tools: after thousands of cycles, even a minor wear or misalignment can cause visible changes in wall thickness, fit, or clarity.

That’s why before each production run, our engineers clean, recalibrate, and test the mold under controlled conditions.

They measure dimensions, check the gate balance, and verify that the cooling and ejection systems are functioning perfectly.

If any deviation appears, adjustments are made immediately before production begins.

We do this not because the client asked — most clients never see this step —

but because it’s the foundation of consistency.

A mold that’s off by 0.1 mm can make an entire batch look “different.”

And in beauty packaging, “different” is exactly what your brand can’t afford.

Material Control: Keeping Consistency Starts with Stable Raw Materials

Once the molds are verified, the next factor that determines product consistency is the material itself.

Even with the same mold, unstable resin or inconsistent color masterbatch can make two batches look completely different under lighting.

That’s why every new order begins with a full raw material check.

We test melt flow rate, color dispersion, and density for every batch of PP, PET, or PE before production starts.

If there’s even a slight deviation from the standard value, the material is flagged, rechecked, or replaced.

This process might look repetitive, but it prevents bigger problems later — color drift, brittleness, or poor surface finish that could affect your entire product line.

We keep detailed data for each lot, so if you reorder months later, we can match the same formula and performance.

Stable material is the foundation of visual and structural consistency.

It’s how we make sure what you approved the first time, looks exactly the same in every repeat order.

Golden Sample Confirmation: The Bridge Between What You See and What We Make

In packaging projects, what you approve as a sample is only the starting point.

The real challenge is making sure every batch that follows looks exactly the same.

That’s why we treat every approved sample as a golden sample — a physical standard that connects your visual expectation with our production process.

It’s photographed, labeled, and stored under controlled lighting in our QC room.

Before every production run, our team compares the first-off piece with this golden sample under the same conditions: color tone, gloss level, wall thickness, and fit.

Only when everything aligns perfectly do we start full production.

This step might look simple, but it’s what keeps your brand consistent.

The golden sample eliminates guesswork — it makes “approved” mean the same thing for designers, QC, and machine operators.

It’s how we turn one sample into thousands of identical pieces, without changing what you approved.

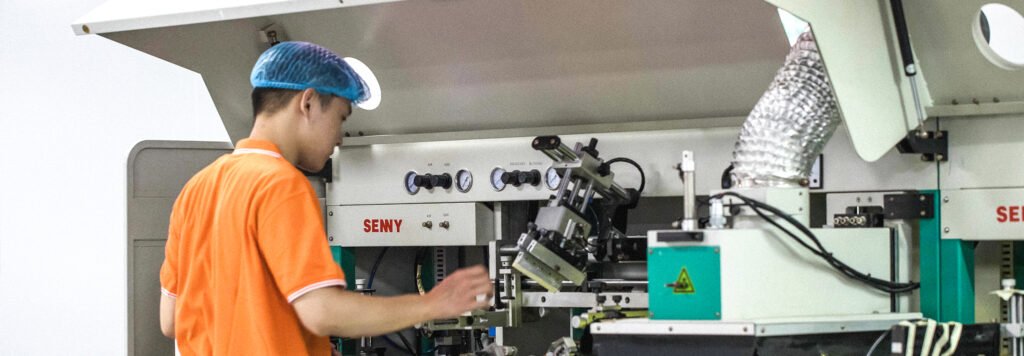

In-process QC: every few hours, we talk to the data

Once production begins, the machines run continuously — but quality control never stops.

Our QC team monitors each line at set intervals, checking color tone, fit precision, surface gloss, and pump performance.

Every few hours, random samples are tested and recorded, allowing us to spot small deviations before they turn into costly issues.

We don’t wait for defects to appear.

Instead, we use data trends — such as wall thickness, color delta, and weight variations — to anticipate changes early.

If a shift is detected, the line pauses for recalibration until every parameter returns within tolerance.

This preventive control is what keeps production stable and predictable.

It’s also why our clients often tell us: “You catch problems before we even notice them.”

That’s exactly how a reliable packaging supplier should work — quietly preventing risks, not reacting to them.

Pre-Shipment Inspection & Batch Traceability: Making Every Batch Accountable

Before shipment, every batch goes through a final QC review.

Cartons are opened, samples are compared with the golden standard, and details like pump fit, gloss level, and bottle clarity are rechecked.

Only after the QC team signs off, the goods are cleared for packing.

But our process doesn’t end there.

For every shipment, we keep retained samples — along with the inspection reports, production time, and machine data — archived for at least 12 months.

This allows us to trace any issue back to its exact batch, mold, and production line.

For clients, this means two things: transparency and security.

You don’t need to guess what happened — we can show you.

That’s what it means when we say “quality that can be verified,” not just “promised.”

Consistency Is Not an Accident — It’s a System Built for Trust

In B2B packaging, quality consistency doesn’t happen by chance — it’s engineered through process.

From mold verification to material control, from golden sample alignment to in-process inspection and batch traceability — every step exists for one reason: to make results repeatable.

That repeatability is what protects your brand image, keeps your launch timeline safe, and makes your packaging supply chain reliable in the long run.

It’s not about one good shipment — it’s about every shipment being good, predictable, and the same.

At XUMIN Packaging, we’ve learned that trust is built quietly — through thousands of small confirmations that your order will arrive exactly as you approved.

That’s why we say: quality isn’t inspected at the end — it’s designed, recorded, and proven along the way.

If you’re building a brand that values reliability, we build packaging that keeps that promise visible.